Ultrasonic Antifouling

With our respected team of product, sales and service professionals, Australian Marine Sales is your ‘one-stop’ solution for all your boating needs, including expert installation services

Recreational Power & Sail Vessels

Choose Yacht Shield by Australian Marine Sales for an elevated boating experience, providing you with increased time on the water and substantial cost savings. Australian made and supplied, Yacht Shield delivers superior protection and exceptional value. Renowned by boat owners worldwide and installed by Australian Marine Sales, Yacht Shield technology stands out as the ultimate choice for those seeking the most effective antifouling solution available.

Yacht Shield keeps your hull cleaner for extended periods, reducing the need for frequent and intensive abrasive hull cleaning and significantly prolonging the lifespan of your bottom paint. With continuous antifouling protection, Yacht Shield Ultrasonic systems, installed by Australian Marine Sales, proactively target and prevent biofouling from forming on hulls, drives, rudders, thrusters, and more.

AMS Expert Team

Our dedicated team brings a wealth of knowledge and expertise to assist you every step of the way. With their in-depth understanding of our products and their commitment to customer satisfaction, you can trust our team to provide personalised assistance and expert advice to help you make informed decisions about your Yacht Shield.

Continuous Antifouling

Yacht Shield systems effectively work 24/7 to repel most types of marine fouling

Improve Performance

A clean hull has less drag, improved fuel efficiency, and increased top-end speed.

Save Money & Time

Spend less money and time with fewer haul-outs, bottom painting, and abrasive cleaning.

Easy Installation

Installation is straight-forward, easy and does not require special tools.

Environmentally Friendly

Use less applications of toxic bottom paint while reducing environmental impact.

Increase Resale Value

Boats having automated anti-fouling hardware have increased resale value.

Commercial Vessels

Yacht Shield, supplied by Australian Marine Sales and offers the organisation of installation with reputable trades. From hulls to shafts, props to pod-drives, jet-drives to steering and control gear, sea chests to box coolers, and pipework to valves, our systems ensure thorough coverage. Additionally, they safeguard keel coolers, heat exchangers, RSW cooling systems, and bulk storage tanks, providing a complete solution for marine operators.

By choosing Yacht Shield, operators can experience benefits such as reduced fuel consumption, lower emissions, improved performance, enhanced handling, extended service intervals, and increased asset lifespan.

Supplied by AMS

Australian Marine Sales proudly offers the supply and organisation of installation of Yacht Shield, Australian-made for marine protection. Yacht Shield embodies superior craftsmanship and durability, tailored to withstand harsh marine environments. Trust Australian Marine Sales to deliver Yacht Shield, safeguarding your vessel and enhancing your boating experience.

How It Works

Yacht Shield effectively shield vessels from the damaging effects of marine biofouling. Our ultrasonic systems harness advanced ultrasound technology to deter microorganisms from adhering to surfaces exposed to raw seawater. By transmitting ultrasound wave energy through these surfaces, a thin layer of high pressure is generated, forming a protective barrier that obstructs the passage of fouling organisms.

In simpler terms, each ultrasound pulse induces subtle vibrations in the surface material, repelling fouling organisms and ensuring surfaces remain cleaner for longer periods. Trust Yacht Shield, delivered by Australian Marine Sales, to uphold the pristine condition of your vessel.

Benefits of Ultrasonic Antifouling

Maintaining a clean hull dramatically increases performance, speed, and overall fuel efficiency. Yacht Shield ultrasonic antifouling ensures you’re vessel is running at peak performance.

Contact an AMS Expert Today

Phone: 1300 795 531

Ultrasonic Antifouling

Revolutionising Marine Maintenance

Ultrasonic antifouling technology offers a modern solution to an age-old problem faced by boat owners and the marine industry—biofouling. Biofouling, the accumulation of microorganisms, plants, algae, or animals on wetted surfaces, presents a significant challenge as it can decrease a vessel’s performance and increase fuel consumption. By employing high-frequency sound waves, ultrasonic antifouling systems prevent the growth of unwanted organisms on a boat’s hull, thereby maintaining its efficiency and reducing the need for harsh chemical antifouling paints.

Installing an ultrasonic antifouling system involves fitting transducers inside the hull, emitting sound waves that create an environment inhospitable to potential

foulers. This non-toxic approach is gaining traction as an eco-friendly alternative to conventional methods, resonating with the growing awareness and regulation around marine preservation. It operates silently and can be used on various types of vessels, making it an adaptable solution for the industry.

The technology, while advanced, is designed for straightforward operation and is accessible for boat owners looking to protect their investment and contribute to environmental conservation. As research and development continue, advancements in ultrasonic antifouling systems are expected to enhance their effectiveness and efficiency, positioning them as a competitive option in the market.

Key Takeaways

Ultrasonic antifouling employs sound waves to prevent biofouling on boat hulls, improving vessel performance.

The system offers an eco-friendly alternative to traditional chemical antifouling treatments.

Advancements in technology are increasing the effectiveness and market appeal of ultrasonic antifouling systems.

Fundamentals of Ultrasonic Antifouling

Ultrasonic antifouling is a technology that uses sound waves to prevent the accumulation of organisms on submerged surfaces. It’s important to understand its effectiveness and the mechanism behind how it deters biofouling.

Does Ultrasonic Antifouling Really Work?

Reports and studies suggest that ultrasonic antifouling systems can be effective in preventing biofouling. These systems generate sound waves that create an environment that is not conducive to the growth of marine organisms. Frequency and power output are critical factors in the efficacy of these systems.

Users, you should evaluate the quality of the system and the conditions in which your vessel operates, as these influence the performance of ultrasonic antifouling. Performance can vary, but many users experience reduced growth compared to untreated surfaces.

How Ultrasonic Waves Prevent Fouling

Ultrasonic waves work on the principle that sound waves at specific frequencies create vibrations in the material they pass through. These vibrations discourage marine organisms from settling and growing on hulls, props, and other underwater metal structures.

- Mechanism: When ultrasonic waves hit the surface, they create an unfavourable environment for biofouling organisms.

- Frequency Range: Typically, frequencies between 20 and 40 kHz are utilised, tailored to disrupt the life cycle of common fouling organisms.

Ultrasonics don’t eliminate the need for regular maintenance, but they can significantly reduce the rate of biofouling. They effectively prolong periods between cleaning and reduce the reliance on chemical antifouling treatments. Remember, they’re a preventive measure, not a cure.

Components of Ultrasonic Antifouling Systems

Ultrasonic antifouling systems are designed to keep your boat’s hull clean without the need for toxic paints. Central to their effectiveness are the transducers and control units that form the core of the system.

Antifouling Paints

Antifouling paints are traditional coatings applied to the hull of a boat to prevent organisms such as barnacles and algae from attaching. Historically, these paints contain biocides, typically copper or tin compounds, which deter marine growth. Unlike ultrasonic antifouling, which uses sound waves to prevent fouling, antifouling paints create a toxic barrier.

- Efficacy: Antifouling paints generally work well initially but can decrease effectiveness as the paint releases its biocide over time.

- Maintenance: You must reapply antifouling paint periodically, typically every one to three years, depending on the paint type and your boat’s usage.

- Environment: These paints can be detrimental to marine life due to the leaching of chemicals, an issue not present with ultrasonic systems.

Mechanical Cleaning Methods

Mechanical cleaning includes methods like scraping, water jetting, and hull brushing to physically remove fouling from your vessel’s hull. These methods can be labour-intensive and may require dry docking of the boat.

- Efficacy: Mechanical methods effectively remove developed fouling but do not prevent new growth, unlike ultrasonic antifouling, which continually deters organisms.

- Maintenance: More frequent attention is often required, with some boat owners performing mechanical cleaning several times per year.

- Environment: Mechanical cleaning can have minimal ecological impact, but it often results in the immediate release of fouling organisms and biocides from old paint into the water.

Market and Industry Applications

In the marine sector, ultrasonic antifouling technology is pivotal for maintaining vessel performance and reducing maintenance costs. Adopted across various industry segments, it offers a clean and efficient solution to biofouling.

Commercial Shipping

Commercial shipping is a significant segment incorporating ultrasonic antifouling systems to protect submerged hulls and surfaces. Your fleet efficiency relies on these systems to reduce drag and fuel consumption spurred by biofouling. Market trends suggest a growing demand for these systems as regulations tighten on environmental impacts and biosecurity risks associated with vessel-borne invasive species.

- Applications: hulls, tanks, seachests

- Benefits:

- Fuel Efficiency: sizable reductions in fuel consumption

- Maintenance: decreased dry-docking frequency

Recreational Vessels

Recreational vessels, from yachts to motorboats, greatly benefit from ultrasonic antifouling applications. Your vessel must maintain speed and aesthetic appeal, which these systems ensure without the frequent need for hull scrubs and paint jobs.

- Systems: transducers strategically placed along the hull

- Market Adoption:

- High: particularly in regions with warmer waters conducive to rapid marine growth

Using strategic placement of ultrasonic devices within your vessel’s structure can extend the lifetime of coatings and components, ultimately protecting your investment.

Advancements and Innovations

In the field of ultrasonic antifouling, transducer technology has significantly improved. Modern transducers are compact and energy-efficient, producing high-frequency ultrasound waves with greater precision. The innovative application of these waves has broadened the scope of antifouling systems and enhanced their performance.

Advancements in innovation and development include:

- Smart Control Systems: integration of microcontrollers that automate the ultrasonic output based on fouling levels

- Multi-Frequency Outputs: systems that vary frequencies to target a broader range of organisms

Iterative Developments

As you explore the latest antifouling solutions, consider the materials used in transducers. Recent developments include improved water resistance and longevity through the use of advanced composites.

Future Outlook

As transducer technology evolves, you’ll see systems that adapt to different water salinities and temperatures, ensuring optimal performance in variable conditions. Furthermore, advancements in ultrasound have led to:

- Increased Power Efficiency: lower power consumption while maintaining efficacy

- Enhanced Coverage: larger hulls can now be effectively protected

- Reduced Environmental Impact: ultrasound provides a non-toxic method for preventing biofouling and safeguarding marine ecosystems

Frequently Asked Questions

This section addresses common inquiries regarding costs, effectiveness, supplier options, kit components, and eco-friendly alternatives for ultrasonic antifouling systems.

What is the typical cost range for installing an ultrasonic antifouling system?

The cost of installing an ultrasonic antifouling system on your boat can vary significantly depending on the size of the vessel and the complexity of the system. Prices generally range from AUD 1,000 to over AUD 5,000.

Which ultrasonic antifouling system is considered the most effective for yacht maintenance?

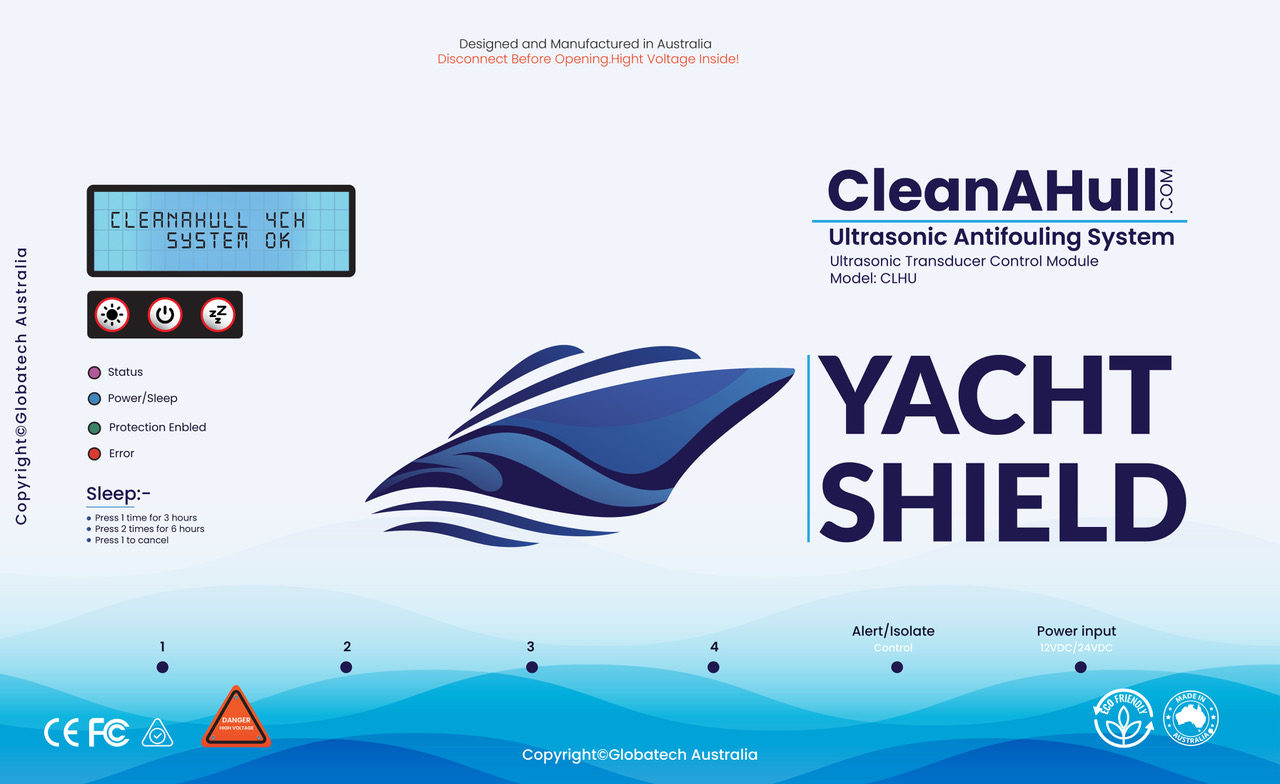

The effectiveness of an ultrasonic antifouling system can depend on various factors, including the yacht’s size and the local marine conditions. Systems produced by established brands like UltraSonic Antifouling Ltd and CleanAHull are widely regarded as effective choices for yacht maintenance.

How do reviews rate the performance of ultrasonic antifouling systems in marine environments?

Reviews typically rate ultrasonic antifouling systems positively, noting reductions in marine growth and maintenance requirements. However, performance can vary by brand and specific marine environment.

What are the components of a complete ultrasonic antifouling kit?

A complete ultrasonic antifouling kit usually includes ultrasonic transducers, a control unit, cables for connection, and mounting hardware. Instructions for installation and use are also typically provided.

Are there any reputable suppliers of ultrasonic antifouling systems in Singapore?

Several reputable suppliers in Singapore offer ultrasonic antifouling systems, including Marine Works Asia and Ultrasonic Antifouling International. These suppliers provide systems suited to the local maritime conditions.

What are the eco-friendly alternatives to traditional antifouling paints for ships?

Eco-friendly alternatives to traditional antifouling paints include silicone-based coatings, biocide-free foul-release coatings, and ultrasonic antifouling systems, which prevent growth without releasing harmful substances.

Thinking of selling your boat

Talk to us about listing and marketing your boat using our database of serious boating enthusiasts